Meta Phenylene Diamine ( MPD )

Meta Phenylene Diamine ( MPD ) Specification

- Molecular Weight

- 108.1 Grams (g)

- Density

- 1.14 Gram per cubic meter (g/m3)

- EINECS No

- 203-584-7

- Solubility

- Solubility in water 42.9 g/100 ml

- Physical Form

- Solid

- Appearance

- White solid

- Melting Point

- 64 to 66 C

- Usage

- Raw materials used in a variety of products and industries (e.g. in cosmetics, chemical manufacturing, production of metals, etc);

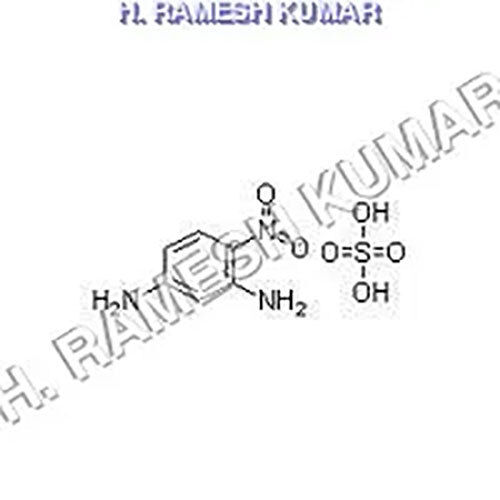

- Molecular Formula

- C6H8N2

- Product Type

- Industrial

- Refractive Rate

- 1.6339

- Grade

- INDUSTRIAL

- Purity

- 99%

- Shape

- Crystal

- CAS No

- 108-45-2

Meta Phenylene Diamine ( MPD ) Trade Information

- Minimum Order Quantity

- 225 Kilograms

- FOB Port

- Mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5000 Kilograms Per Day

- Delivery Time

- 1-7 Days

- Packaging Details

- 25/50 KG BAG

- Main Domestic Market

- All India

About Meta Phenylene Diamine ( MPD )

The chemical compound known as Meta-Phenylenediamine (MPD) has the molecular formula C6H8N2. A common building block in the creation of numerous polymeric materials, such as plastics, resins, and fibers, is MPD. The production of polyamide fibers, such as nylon, uses MPD as one of its most frequently used applications. Given that Meta-Phenylenediamine (MPD) is regarded as a hazardous substance, the proper safety measures should be taken when handling it. Adipic acid and MPD are combined to create nylon 6,6, a polymer that is frequently used in carpeting, clothing, and other products. Epoxy resins, which are used in composites, coatings, and adhesives, are also made using MPD.

Versatile Applications in Industry

Meta Phenylene Diamine serves as a critical raw material in cosmetic formulation, chemical processing, and metal production industries. Its high purity and crystalline form make it ideal for specialized manufacturing processes requiring reliable and consistent performance. The chemicals adaptability and effectiveness drive its widespread demand across India.

Consistent High Quality

Supplied at an industrial grade with 99% purity, MPD offers dependable quality for strict production protocols. Its precise molecular propertiessuch as refractive rate and densityensure that manufacturers and researchers can rely on predictable results, maintaining stringent standards in both quality assurance and regulation.

FAQs of Meta Phenylene Diamine ( MPD ):

Q: How is Meta Phenylene Diamine (MPD) commonly used in industrial sectors?

A: MPD is utilized as a raw material in the formulation of cosmetics, chemical manufacturing processes, and the production of metals. Its versatility also extends to specialized applications where a high-purity compound is required.Q: What benefits does using MPD offer to manufacturers?

A: Manufacturers benefit from MPDs high purity (99%), consistent crystalline form, and substantial solubility in water, allowing for efficient processing, enhanced product quality, and compliance with industrial standards.Q: When should MPD be selected for a production process?

A: MPD should be considered when your manufacturing requires a reliable intermediate with a stable melting point, high solubility, and excellent purity, especially in cosmetics, metal processing, or chemical synthesis.Q: Where can MPD be sourced in India?

A: MPD is available through a wide network of distributors, exporters, importers, suppliers, traders, and wholesalers across India, ensuring wide accessibility for various industrial needs.Q: What is the typical process for incorporating MPD into industrial applications?

A: Depending on the end-use, MPD is dissolved, reacted, or otherwise formulated as a component in chemical syntheses, metal treatment solutions, or cosmetic bases, taking advantage of its solid crystalline form and high purity.Q: Is MPD suitable for industries requiring stringent chemical standards?

A: Yes, with certifications such as CAS No: 108-45-2 and EINECS No: 203-584-7, and its industrial-grade 99% purity, MPD meets rigorous requirements for quality and traceability in demanding sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in M Symbol Chemicals Category

Meta Nitro ( MNT )

Price Range 170.00 - 250.00 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Appearance : YELLOW LIQUID WITH CHARACTERISTIC ODOUR

Physical Form : Liquid

Molecular Weight : 137.138 Grams (g)

CAS No : 99081

Meta Amino Phenol ( MAP )

Price Range 800.00 - 900.00 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Appearance : White crystals or offwhite flakes

Physical Form : Powder

Molecular Weight : 109.128 Grams (g)

CAS No : 591275

Meta Toluidine

Price Range 250.00 - 350.00 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Appearance : Clear Yellow Liquid Which Darkens on Standing

Physical Form : Liquid

Molecular Weight : 107.156 Grams (g)

CAS No : 108441

3-methyl 5-pyrazolone.

Price Range 800.00 - 900.00 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Appearance : White to Offwhite Crystalline freeflowing PowderÂ

Physical Form : Powder

Molecular Weight : 98.00 Grams (g)

CAS No : 108269

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS